Why LED-enhanced Rubber Keypads are growing in demand in modern devices

Finding the Diverse Makes Use Of and Enters of Rubber Keypads in the Modern Technology Landscape Today

Rubber keypads have actually established themselves as important components in different technological applications. Their adaptability makes them suitable for consumer electronics, commercial makers, and medical devices. As these keypads proceed to advance, brand-new modification alternatives and style patterns emerge. This triggers a more detailed examination of their advantages and making processes. Understanding these components may reveal why rubber keypads continue to be a favored option in the technology landscape. What exists ahead for this functional element?

Summary of Rubber Keypads

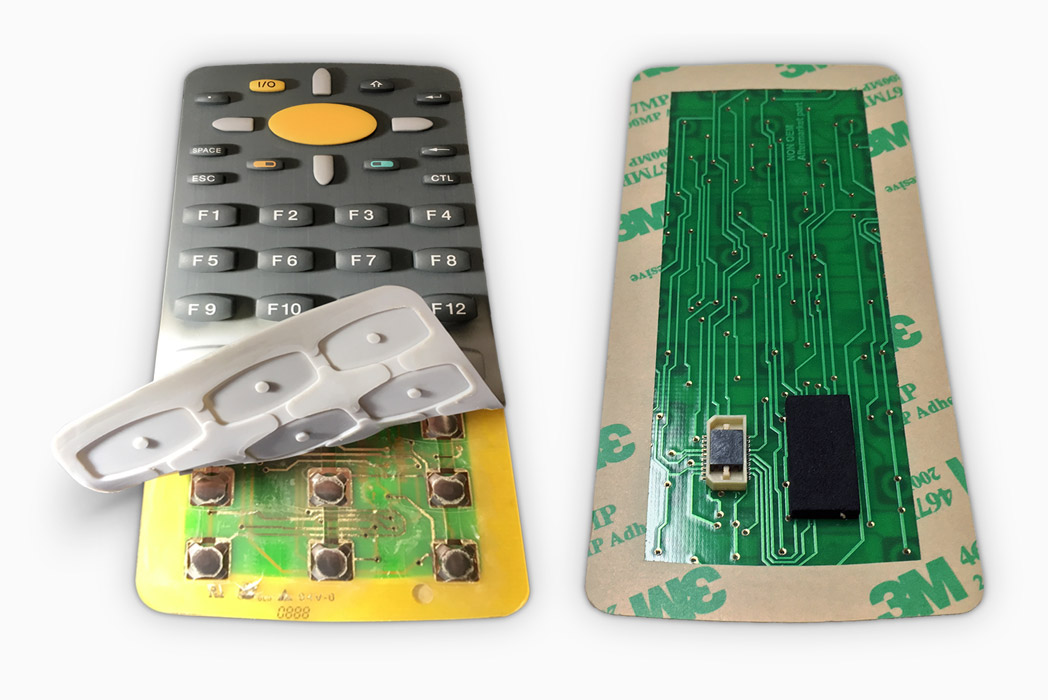

Rubber keypads offer as an essential component in numerous electronic gadgets, using a tactile interface for individual interaction. These keypads are usually made from silicone or rubber materials, which supply versatility and resilience. Their design often incorporates elevated signs or letters, improving usability by allowing individuals to feel the keys - Rubber Keypads. Rubber keypads are resistant to dirt, moisture, and wear, making them suitable for demanding environments

Additionally, they can be personalized relating to form, size, and shade, allowing manufacturers to produce unique user interfaces customized to certain products. The production procedure typically entails techniques such as molding and printing, guaranteeing top notch outcome. Consequently, rubber keypads not only improve performance but also add to the general aesthetics of the tool. With these features, rubber keypads continue to be a preferred choice for both makers and consumers, stressing their significance in the innovation landscape.

Usual Applications in Customer Electronic Devices

While many electronic tools rely upon touchscreens for customer communication, rubber keypads remain to play a vital role in consumer electronic devices. These keypads are commonly made use of in devices such as push-button controls, gaming controllers, and family appliances, where tactile responses enhances individual experience. Their resilience and resistance to use make them perfect for devices regularly based on hefty use.

Rubber keypads are likewise popular in portable gadgets and mobile phones, where portable designs require responsive and trusted input methods. The capability to customize the shape and structure of rubber keypads enables makers to produce distinct styles that appeal to consumers. Additionally, the soft touch of rubber provides comfort throughout extended use, making these keypads a favored option for tools requiring prolonged communication. Overall, rubber keypads continue to be a vital element in the customer electronic devices landscape, combining capability with easy to use features.

Function in Industrial and Medical Tools

Rubber keypads play a crucial function in both industrial and medical devices, providing sturdiness and integrity in requiring settings. In commercial setups, they are typically used in control panels and machinery, improving operator communication with complex systems. In the medical area, rubber keypads help with straightforward user interfaces for tools that require precision and hygiene.

Industrial Equipment Applications

Keypads play a crucial function in the functionality and individual experience of commercial and medical devices. In commercial setups, rubber keypads offer a durable interface for equipment and control systems, permitting operators to conveniently input commands and change setups. Their resistance to dirt, wetness, and chemicals guarantees dependability under rough conditions normal of factories and manufacturing plants. In addition, the tactile responses supplied by rubber keypads enhances customer interaction, minimizing the possibility of input errors. Along with typical equipment, these keypads are integral in automated robotics and systems, where precision is paramount. The flexibility of rubber keypads in various industrial applications underscores their relevance in improving functional efficiency and guaranteeing safety and security in complex settings.

Medical Gadget Integration

As clinical devices increasingly call for user-friendly user interfaces, the combination of rubber keypads has ended up being essential in making sure effective interaction in between health care experts and equipment. These keypads provide tactile responses, assisting in instinctive procedure also in high-pressure environments. Their toughness and resistance to harsh cleaning representatives make them ideal for medical settings, where hygiene and durability are essential. Additionally, rubber keypads can be personalized to include various shapes, sizes, and shades, enhancing aesthetic recognition and access for individuals. This flexibility permits the production of specialized controls tailored to details clinical features, enhancing overall efficiency. The duty of rubber keypads in medical tool assimilation not just boosts capability however likewise promotes client safety and security and operational reliability in healthcare atmospheres.

Customization Options and Layout Trends

Recent layout trends stress minimalism and comfort designs, focusing on customer convenience and intuitive interaction. Custom-made logos and branding can be integrated right into keypads, permitting companies to preserve a natural brand identification across their products. Furthermore, advancements in making methods, such as silicone Click This Link molding, have made it less complicated to achieve detailed designs and individualized layouts.

Advantages of Rubber Keypads Over Other Kinds

Rubber keypads are likewise recognized for their resilience and resistance to ecological elements. They can endure temperature level, wetness, and dust changes, making them suitable for industrial or exterior settings. In addition, rubber keypads are often quieter than their plastic or metal counterparts, reducing sound pollution in shared settings.

Furthermore, the cost-effectiveness of rubber keypads makes them an eye-catching choice for suppliers. Their light-weight nature adds to lower shipping prices, while their adjustable styles provide to certain branding demands. On the whole, rubber keypads stand for a flexible and trustworthy service in the modern technology landscape.

Production Techniques for Quality and Resilience

In the production of rubber keypads, the option of suitable products and molding processes plays an essential duty in figuring out general top quality and resilience. Numerous molding techniques, such as compression and injection molding, greatly influence the end product's performance. Recognizing these aspects is necessary for accomplishing suitable outcomes in rubber keypad production.

Molding Processes Discussed

A variety of molding processes play an important duty in the production of rubber keypads, making sure both top quality and durability. The most usual strategies include compression molding, transfer molding, and shot molding. Compression molding involves placing rubber in a warmed mold and mildew, where warm and stress form it right into the desired form. Transfer molding enables even more exact control over material flow and is appropriate for complex styles (Rubber Keypads). Injection molding, recognized for its speed and efficiency, infuses liquified rubber right into a mold under high pressure, creating high-volume get rid of constant high quality. Each approach uses distinctive advantages, influencing aspects such as production cost, rate, and style versatility, eventually impacting the performance and lifespan of rubber keypads in numerous applications

Material Option Importance

Product choice plays a vital role in the production of rubber keypads, directly affecting their performance and sturdiness. The option of rubber substances, such as silicone or polyurethane, impacts responsive feedback, resistance to put on, and ecological resilience. Premium products ensure that keypads can endure substantial use, maintaining their performance over time. In addition, the solution of rubber impacts its resistance to temperature variations and direct exposure to chemicals, which are important for devices in different settings. Utilizing innovative production strategies, such as compression or shot molding, more enhances the architectural honesty of keypads. Eventually, careful product selection and manufacturing procedures add considerably to the overall high quality, durability, and individual contentment of rubber keypads in today's modern technology landscape.

Future Fads in Rubber Keypad Technology

As modern technology remains to advance, the future of rubber keypad advancement shows up promising, with improvements positioned to improve capability and user experience. One notable fad is the integration of touch-sensitive technology, making it possible for capacitive responses that mimics the feeling of traditional buttons while supplying boosted responsiveness. In addition, the development of antimicrobial products is most likely to gain grip, addressing hygiene problems in shared and public tools.

In addition, customization options are expected to increase, permitting users to personalize vital layouts and tactile comments, consequently satisfying varied needs. The incorporation of clever modern technology, such as connection attributes, may likewise emerge, permitting rubber keypads to interact with various other devices discover here seamlessly. As manufacturers concentrate on sustainability, environment-friendly products are expected to come to be a lot more widespread, lining up with global environmental objectives. Generally, these patterns guarantee to change rubber keypads, making them a lot more versatile, straightforward, and environmentally aware in the innovation landscape.

Frequently Asked Concerns

Exactly How Do Rubber Keypads Contrast in Price to Various Other Keypad Types?

Rubber keypads typically supply an affordable solution contrasted to other keypad types, such as membrane layer or mechanical options. Their lower manufacturing expenses and durability make them an eye-catching choice for numerous applications in innovation.

What Are the Environmental Impacts of Rubber Keypad Production?

The environmental impacts of rubber keypad manufacturing consist of resource exhaustion, energy consumption, and air pollution from manufacturing procedures. Additionally, incorrect disposal can cause plastic waste, contributing to environmental destruction and damaging ecosystems otherwise managed sensibly.

Can Rubber Keypads Be Made Use Of Outdoors?

Rubber keypads can be utilized outdoors due to their sturdiness and resistance to weather aspects. Their long life may depend on the top quality of products used and the certain environmental problems they are exposed to.

What Maintenance Is Required for Rubber Keypads?

Rubber keypads call for regular cleaning to eliminate dirt and particles, regular evaluation for damage, and security from severe temperature levels. Making certain proper storage conditions can extend their lifespan and keep functionality with time.

Exactly How Do Rubber Keypads Perform in Extreme Temperatures?

Rubber keypads generally maintain capability in extreme temperature levels, showing strength to both cold and heat. Nonetheless, long term direct exposure might cause material degradation, influencing their responsive action and general performance in harsh settings.

Rubber keypads offer as a fundamental component in different electronic gadgets, offering a tactile user interface for individual communication. While several electronic tools depend on touchscreens for user interaction, rubber keypads proceed to play an essential function in consumer electronic devices. Furthermore, the soft touch of rubber provides comfort during prolonged usage, making these keypads a preferred selection for tools requiring extensive communication. Regardless of the expanding range of keypad materials available, rubber keypads offer unique benefits that make them a favored option in numerous applications. Rubber link keypads normally provide an economical solution compared to other keypad kinds, such as membrane or mechanical choices.